Lignocellulosic fibres are gaining interest as renewable and biodegradable alternatives to single-use plastics. Wood pulp fibres, e.g., thermomechanical (TMP) and chemi-thermomechanical pulp (CTMP), are promising due to high yield in the production, low cost, and sustainable processing.

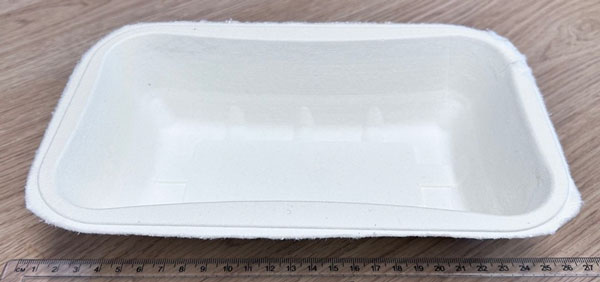

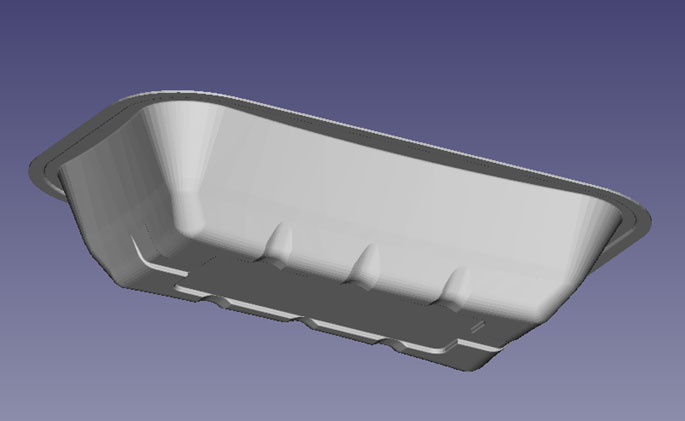

In addition to specializing in characterizing these fibres for use in thermoformed food packaging, RISE PFI is developing technology for thermoforming processes such as wet-moulding and dry-forming. Dry-forming reduces water and energy use compared to wet-forming, with cycle times under 10 seconds per unit. However, there are challenges with deep geometries in dry-forming which are being addressed in the REDYSIGN project. RISE PFI has comprehensive experience on digital modeling and 3D printing that is applied to improve mould designs. Based on this, demonstrators using natural materials like wood pulp fibres, micro/nanofibrillated cellulose and lignin for strength and moisture resistance have been developed.

Contact: Gary Chinga Carrasco