NORCELlab – The Norwegian Cellulose Laboratory – is a national infrastructure dedicated to cellulose research and development, hosted by RISE PFI and funded by the Research Council of Norway.

NORCELlab is available both to national and international stakeholders (universities, institutes and industries), providing its services to companies on commercial contract basis as well as to the benefit of research and development projects and education.

If you wish to use our infrastructure, please visit the NORCELlab website to apply for membership. We will contact you after reviewing your application. You can find the website here:

Contribution to research and innovation

NORCELlab represents the whole value chain from production of cellulosic building blocks to development of prototypes from them. The toolbox in NORCELlab includes advanced instrumentation and analysis equipment in addition to laboratory equipment suitable for simulating industrial production methods. Hence, NORCELlab will secure both research on fundamental level and development of products closer to industrialization.

The laboratory is localized at the Gløshaugen campus, making collaboration with other highly relevant infrastructures such as NORFABnode Nanolab and NorBioLab easy.

While the laboratory is still under construction, several key units are already in place – with more to come!

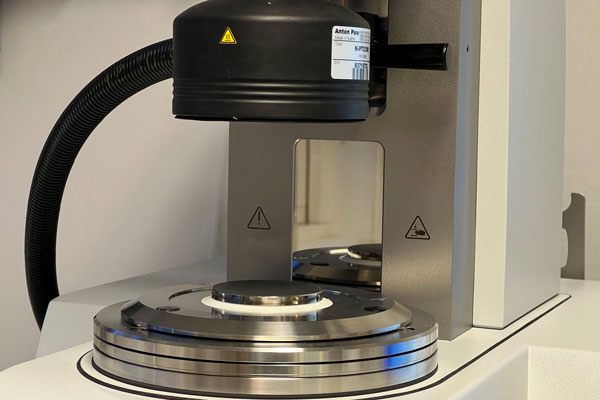

Rheometer

The Anton Paar MCR 702e is an advanced rheometer for studying the flow properties of materials. This instrument can be used to perform both classic and more advanced rheology measurements. The instrument has high rotation speed (up to 3000 RPM) and precise temperature control up to 200°C. We have different geometries that enable analysis on a wide range of samples.

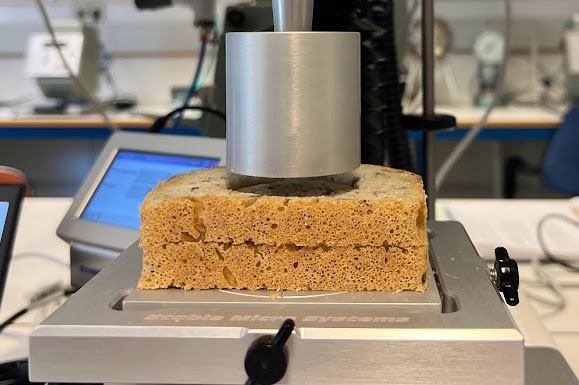

Texture Analyser

The Texture Analyser TA.XT plusC is an analytical instrument used to measure the mechanical and physical properties of various materials, often food products, cosmetics, foams and gels. It measures how hard, tough, soft, or sticky a material is. A “probe” – a type of plunger – is pressed against the sample and measures the force required to deform it, as a function of time. The results provide insight into the texture of the material.

The instrument can be adapted to different materials by using various probes and fixtures.

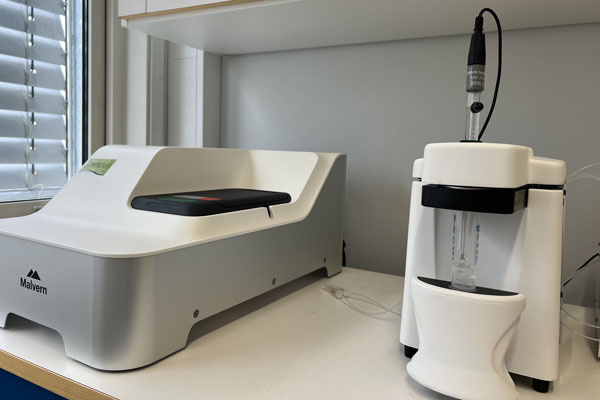

Zetasizer

The Zetasizer Ultra measures the size of small particles in a liquid by analyzing how they scatter light. The Charge can also be measured. It provides insights into particle stability and whether they tend to aggregate. The instrument features precise temperature control and can automatically test how particles behave at different pH levels.

Laboratory Spray Dryer

The spray dryer efficiently and gently transforms a liquid (solution or suspension) into a dry powder.

The process works by atomizing the liquid into fine droplets, which are then rapidly dried in a stream of hot air. The result is a uniform, stable powder that is easier to store, transport, and use in further research or production. The effect of the drying process on the quality of the product can be studied.

Pilot Coater

The pilot coater is designed for coating, and laminating all types of flexible materials, such as paper, films, textiles and metallic foils. Coating is done on a roll-to-roll basis, and both organic and water-based coatings can be applied using various application methods.

Dynamic Mechanical Analyser

The DMA 303 Eplexor tests how materials – such as composites, rubber, and fiber-based materials – respond to bending, stretching, or compression. It measures stiffness, softness, and damping capacity, and how these properties change with temperature and humidity.

The instrument can heat samples up to 800 °C and perform tests under varying humidity levels. It is commonly used to determine the glass transition temperature and to study how a material gradually deforms or loses tension when exposed to prolonged stress.

RISE PFI is part of RISE - Research Institutes of Sweden

RISE PFI is and internationally acknowledged research institute within processes and products based on lignocellulose. RISE PFI´s focus areas are Fibre technology and fibre-based products, Biorefining and Bioenergy and Biopolymers and Biocomposites.

Contact

- Høgskoleringen 6b

- NO - 7491 Trondheim

- firmapost@rise-pfi.no

- +47 73 60 50 65